Space Tourism Rocket Launch Delayed

The Complex Engineering and Technical Hurdles

A space launch is arguably the most complex mechanical and logistical feat humanity performs. It involves coordinating millions of parts, sophisticated software, and extreme environmental conditions. Any single anomaly can necessitate a delay.

A. Rocket System Checks and Component Issues

-

Engine and Propulsion System Integrity: a. Turbopump Anomalies: The high-speed turbopumps feeding fuel and oxidizer into the combustion chamber are under immense stress. Microscopic cracks or sensor reading fluctuations in these critical components can halt a countdown. b. Ignition Sequence Verification: The successful and precise timing of the engine ignition sequence, which often involves pre-burners and complex valving, must be verified down to the millisecond.

-

Structural and Material Stress Testing: a. Cryogenic Fuel Leaks: Liquid oxygen (LOX) and liquid hydrogen (LH2) are stored at extremely low temperatures. Tiny cracks in tanks, seals, or plumbing caused by thermal stress can lead to leaks, creating dangerous explosive risks. b. Fairing and Stage Separation Mechanisms: The mechanisms responsible for protecting the payload and separating stages must function flawlessly. Issues in pyrotechnic devices or latching systems are common delay culprits.

B. Avionics and Software Verification

-

Guidance, Navigation, and Control (GNC) System Glitches: The flight control software is the brain of the rocket. Bugs or unexpected telemetry data from accelerometers, gyroscopes, or star trackers require immediate troubleshooting, which can take days or weeks.

-

Communication and Telemetry Links: Loss of redundant communication links between the rocket and ground control, or issues with data relay satellites, often trigger automatic holds in the countdown.

-

Range Safety System Compliance: The autonomous flight safety system, designed to terminate the flight if the rocket veers off course towards populated areas, must be confirmed to be 100% operational and armed before launch.

C. Ground Support and Launch Infrastructure

-

Launch Pad Systems Failure: The pad itself is a complex machine, including fluid transfer lines, electrical power systems, and deluge systems for noise suppression. A malfunction in any of these fixed systems requires repair before fueling can commence.

-

Tracking and Radar Dish Calibration: The vast network of ground and sea-based tracking stations necessary to monitor the rocket’s trajectory must be perfectly aligned and operational. Calibration issues often lead to range closures and subsequent delays.

External Factors and Regulatory Oversight

Not all delays originate within the rocket itself. External forces, particularly weather and governmental regulations, play a critical role.

A. Weather Constraints and Environmental Conditions

-

Upper-Level Wind Shear: High-altitude winds can exert excessive aerodynamic loads on the vehicle as it ascends through the atmosphere, potentially leading to structural failure. Launch windows are often closed if wind shear limits are exceeded.

-

Cumulus Clouds and Electric Fields: Launching through thick cloud layers, especially those that generate strong electric fields, increases the risk of induced lightning strikes, which can severely damage or destroy sensitive avionics.

-

Ground Winds and Crosswinds: High surface winds at the launch site can make rolling the rocket out to the pad or stabilizing it during fueling dangerous, especially for taller vehicles.

-

Rain and Temperature Extremes: Heavy rain can affect ground equipment and potentially cause issues with insulation, while extreme temperatures can compromise fuel storage or structural integrity.

B. Regulatory and Safety Compliance

-

Federal Aviation Administration (FAA) Licensing: The FAA’s Office of Commercial Space Transportation (AST) must issue a license for every commercial launch. If safety data, flight termination analysis, or liability coverage documents are incomplete, the license will be withheld or delayed.

-

Range Clearance and Airspace Restrictions: Before a launch, the airspace and downrange hazard areas must be cleared of marine traffic and aircraft. Unexpected incursions or coordination problems with adjacent military or civilian ranges can cause significant holds.

-

Environmental Reviews and Permits: New launch sites or modifications to existing facilities often require extensive environmental impact assessments and permits, which can be subject to lengthy public comment and regulatory approval processes.

Financial and Strategic Implications of Delays

While frustrating for customers and spectators, launch delays have profound business, financial, and competitive consequences for space tourism operators.

A. Economic Costs and Expenditure Overruns

-

Increased Operating Expenses: Every day a rocket sits on the pad adds to staffing, power, and maintenance costs. A scrubbed launch requires the costly process of defueling, safing the vehicle, and re-tanking, which is expensive and time-consuming.

-

Contractual Penalties and Insurance Premiums: Delays can trigger penalties in service contracts. Additionally, repeated scrubs can increase the cost of future launch insurance premiums, especially for unproven vehicle designs.

-

Holding Capital: Funds and resources tied up in the delayed mission cannot be used for the development of future projects or other revenue-generating activities, impacting the company’s capital efficiency.

B. Customer Relations and Market Perception

-

Passenger Frustration and Refunds: High-net-worth customers who have paid hundreds of thousands or even millions of dollars for a seat become frustrated by indefinite delays, potentially leading to demands for refunds and negative publicity.

-

Investor Confidence Erosion: Persistent or recurrent delays, particularly those stemming from fundamental design flaws, can signal instability to investors, potentially leading to stock price volatility and difficulty in raising future capital.

-

Competitive Disadvantage: If a competitor successfully launches first, the delayed company loses the significant market advantage and media attention associated with pioneering a new phase of space exploration.

Case Study: The Safety-First Culture

In the space industry, a delay is rarely seen as a failure; rather, it is viewed as the successful functioning of the safety system. This cultural imperative is central to the viability of space tourism.

A. The Go/No-Go Decision Process

-

Redundant Checks and Sign-Offs: Launches require multiple levels of sign-off from mission directors, vehicle engineers, and safety officers. Any one person can call a “Hold” if they observe an issue, a process known as the “Red Line” authority.

-

Margin of Safety Philosophy: All system parameters are designed and operated well within their theoretical limits. If a measurement approaches a predetermined safety margin, the launch is automatically put on hold, prioritizing safety over schedule.

B. The Long-Term Benefit of Prudence

-

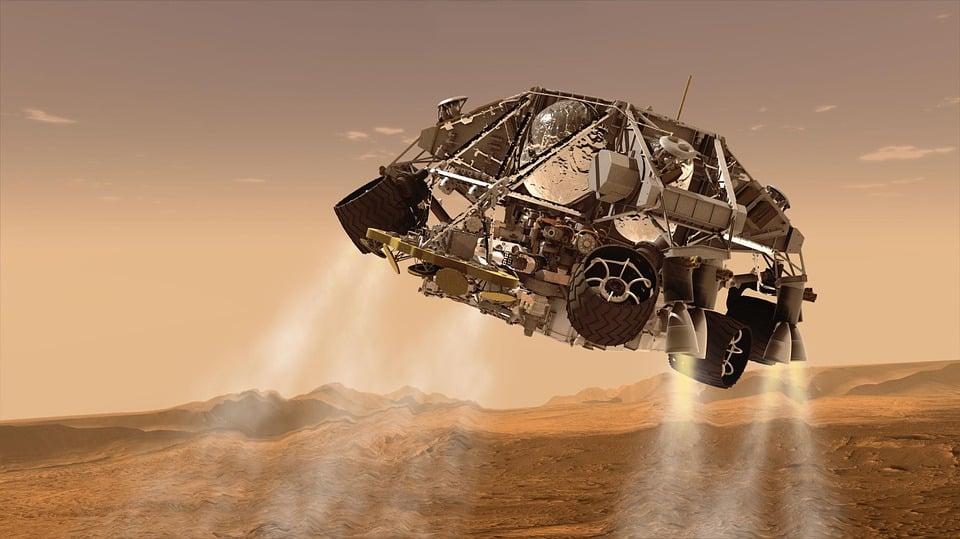

Protecting Human Life: For crewed missions, especially space tourism where the passengers are not professional astronauts, the safety margins are even tighter. A single catastrophic failure would be devastating, setting the entire industry back decades.

-

Preserving Vehicle Investment: Rockets, particularly the reusable vehicles central to the space tourism business model, represent massive capital investments. A delay to fix a minor issue is vastly preferable to an expensive and dangerous loss of the entire vehicle.

Technological Innovations Aiming to Minimize Delays

The industry is actively developing new technologies and operational procedures to increase launch frequency and reliability, thereby reducing the incidence of delays.

A. Enhanced Monitoring and Diagnostics

-

Artificial Intelligence (AI) in Health Monitoring: Integrating AI and Machine Learning (ML) algorithms to analyze real-time sensor data, quickly identifying subtle anomalies that might escape human operators and predicting component failure before it occurs.

-

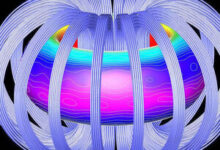

Digital Twin Technology: Creating a high-fidelity digital replica of the rocket and ground systems. This allows engineers to simulate fault scenarios and test fixes virtually before implementing them on the physical hardware.

B. Increased Automation and Reusability

-

Automated Scrub Recovery: Developing automated systems that can quickly assess the nature of a scrub, isolate the issue, and rapidly re-configure the vehicle and pad for a new launch attempt, drastically reducing turnaround time.

-

Rapid Reusability Design: Building vehicles, such as the SpaceX Starship, designed for immediate reuse with minimal refurbishment. This modularity makes system checks quicker and allows for faster substitution of faulty components.

C. Autonomous Flight Safety Systems

-

GPS-Based Tracking: Moving away from reliance on complex, expensive ground-based radar systems to using on-board GPS and sophisticated inertial measurement units for more reliable and rapid flight path determination.

-

Independent Safety Review: Allowing pre-vetted, autonomous safety systems to make “Go/No-Go” decisions based on real-time data, reducing human-in-the-loop dependencies during the most critical phases of the countdown.

Conclusion: The Necessary Patience for the Final Frontier

While the announcement of a Space Tourism Rocket Launch Delayed inevitably brings disappointment, it is a hallmark of an industry that correctly places safety and precision above all else. These postponements are not signs of failure, but rather crucial checkpoints ensuring the integrity of extremely complex, high-energy systems carrying human lives. As space tourism transitions from a niche endeavor to a sustainable industry, continued investment in robust, automated diagnostic tools and rapid reusability will be key to minimizing delays. Ultimately, the industry understands that the long-term success of commercial human spaceflight is dependent on its impeccable safety record, making every necessary delay a responsible investment in the future of orbital travel. The patience demonstrated today paves the way for the routine, safe launches of tomorrow.