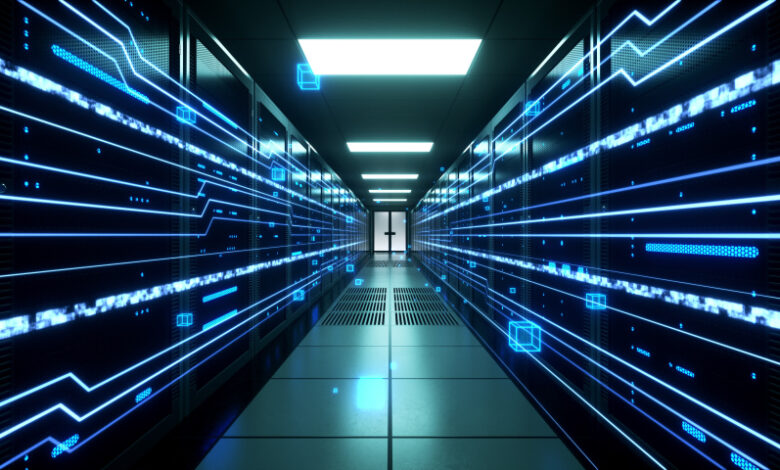

Data Center Cooling Innovation Revealed

The relentless global surge in data consumption, cloud computing, artificial intelligence (AI), and cryptocurrencies has pushed the limits of traditional data center infrastructure. At the core of this challenge lies the escalating heat generated by high-density server racks. The article title, Data Center Cooling Innovation Revealed, aptly focuses on the critical need and recent breakthroughs in thermal management. Cooling systems are no longer a mere auxiliary function; they are the single largest operational expenditure (OpEx) component outside of server hardware itself, often consuming up to 40-50% of the data center’s total energy budget.

The Critical Need for Next-Generation Cooling

The move from the petabyte to the exascale era has resulted in significant increases in server rack power density. A decade ago, a typical rack might draw 5kW; today, AI and high-performance computing (HPC) racks can draw 50kW to over 100kW. Traditional computer room air conditioning (CRAC) units and hot/cold aisle containment, while effective for lower densities, become grossly inefficient and economically unviable at these levels. The key challenges driving innovation are:

A. Increasing Power Density: The physical size constraints of chip manufacturing lead to more transistors packed into smaller spaces, resulting in higher heat flux per unit area (W/cm²).

B. Energy Efficiency and PUE: Data center operators are under immense pressure to reduce their Power Usage Effectiveness (PUE), the ratio of total facility power to IT equipment power. Lowering PUE requires drastically cutting the energy used for cooling.

C. Sustainability and Water Use: Conventional cooling systems, especially evaporative coolers, consume massive amounts of water. Sustainable innovation must prioritize both energy savings and water conservation.

D. Acoustics and Space: Air cooling requires large fans and substantial floor space for air handlers and ducts. Liquid cooling offers a path to quieter, denser infrastructure.

The Evolution of Air-Based Cooling Techniques

Before the deep transition to liquid solutions, significant innovations were made to optimize and extend the life of air-based cooling, focusing on maximizing the efficiency of moving air across hot components.

Hot and Cold Aisle Containment

This foundational method became the industry standard for minimizing air mixing and maximizing the cooling capacity of CRAC/CRAH (Computer Room Air Handler) units.

A. Cold Aisle Containment (CAC): Enclosing the cold aisle to ensure the cold air is directly delivered to the server inlets.

B. Hot Aisle Containment (HAC): Enclosing the hot aisle to capture the exhausted hot air and directly return it to the cooling units for conditioning. HAC is generally more energy-efficient as it maintains ambient room temperature closer to the comfortable range for human staff, while CAC requires the entire room to be chilled.Getty Images

Free Cooling and Economization

A major breakthrough involved leveraging external environmental conditions to reduce or eliminate the need for mechanical refrigeration, thus saving vast amounts of energy.

A. Airside Economization (Air-Side Free Cooling): Using filtered outside air to cool the data center when ambient temperature and humidity are within acceptable limits. This technique is highly effective in temperate and cold climates.

B. Waterside Economization (Water-Side Free Cooling): Using cooling tower water, chilled by the ambient air temperature, to cool the data center water loop via a heat exchanger without activating the mechanical chiller compressors.

Rear Door Heat Exchangers (RDHx)

This hybrid air-liquid approach introduces liquid cooling to the periphery of the rack. A coil filled with chilled water is placed on the rear door of the server rack. As the hot exhaust air leaves the servers, it passes through this coil, transferring its heat to the water before it enters the hot aisle. This significantly reduces the heat load entering the room and returned to the main CRAC units.

The Revolution of Liquid Cooling

As rack power density surpassed 20kW, liquid cooling ceased to be optional and became a necessity. Liquid is thousands of times more efficient than air at transferring heat. The current landscape is dominated by two primary methods.

Direct-to-Chip (D2C) or Cold Plate Cooling

D2C cooling is a form of single-phase liquid cooling that focuses the thermal management directly on the highest-heat components: the CPU, GPU, and memory modules.

A. The Mechanism: A specialized cold plate a sealed metal block with internal microchannels is mounted directly onto the component (CPU/GPU) using thermal interface material. A coolant (often deionized water or a specialized glycol mixture) is pumped through these channels, absorbing the component’s heat before being routed out of the rack to a heat exchanger or chiller.

B. Efficiency and Density: This method can handle densities up to 80kW per rack efficiently. It isolates the heat source, allowing the rest of the facility to maintain higher, less energy-intensive ambient temperatures.

C. Hybrid Implementation: D2C is often implemented as a hybrid system, where the remaining heat from other components (power supplies, storage) is still managed by residual air cooling.

Immersion Cooling (The Game Changer)

Immersion cooling is the most transformative innovation, completely abandoning air in favor of fully submerging IT equipment into a dielectric (non-electrically conductive) liquid. This method offers the highest possible thermal density and PUE improvements.

A. Single-Phase Immersion Cooling: Servers are submerged in a liquid (typically mineral oil or synthetic fluids) that remains in a liquid state. The heated liquid is pumped to a heat exchanger, where the heat is transferred to a facility water loop, and the cooled liquid is returned to the tank. This is a very simple, sealed loop.

B. Two-Phase Immersion Cooling: The servers are submerged in a dielectric fluid with a very low boiling point (e.g., $50-60^\circ$C). The heat generated by the components causes the liquid to boil, turning it into vapor. This vapor rises and condenses on a condenser coil at the top of the tank, turning back into liquid and dripping down (hence “two-phase”). This phase change is incredibly effective at heat transfer.

C. Advantages:

1. Eliminates Fans and Noise: Servers can be manufactured without internal fans, saving energy and improving component reliability.

2. Highest Density: Capable of handling racks over $100$ kW.

3. PUE Near Unity: PUE values can be reduced to $1.05$ or even lower, as mechanical refrigeration is rarely needed.

4. Reduced Footprint: Immersion tanks require less space than traditional air-cooled setups.

Advanced System Optimization and Management

Beyond the physical cooling mechanisms, innovation extends to the intelligence and deployment of these systems, optimizing for specific environmental and operational goals.

Modular and Prefabricated Data Centers (MDC)

The shift to high-density cooling has been facilitated by modular construction. MDC units are pre-built, standardized, and often containerized, allowing for rapid deployment and tailored cooling solutions (like immersion tanks) optimized for their specific load from the start. This allows operators to scale capacity quickly and efficiently.

Artificial Intelligence (AI) and Machine Learning (ML) Optimization

AI is revolutionizing the management of cooling systems by moving beyond static set points. AI algorithms analyze vast streams of operational data server workload, external temperature, humidity, and CRAC unit performance to predict future thermal conditions and dynamically adjust cooling parameters.

A. Predictive Cooling: ML models predict heat load spikes before they occur, preemptively adjusting cooling, which prevents over-cooling and saves energy.

B. Optimal Set Point Determination: AI determines the absolute highest safe temperature and humidity set points, minimizing mechanical cooling hours. Google, for instance, has demonstrated significant energy savings using AI to manage its data center cooling.

Heat Reuse and Waste Heat Recovery

Sustainability is being redefined by transforming waste heat into a valuable resource. This concept closes the energy loop, moving from PUE (efficiency) to Energy Reuse Effectiveness (ERE).

A. Heating Buildings: High-temperature liquid cooling allows the waste heat (which can be over 60 degree Celcius from immersion tanks) to be directly used for district heating, warming nearby residential or commercial buildings.

B. Desalination and Industrial Processes: In regions requiring water purification, data center waste heat can be used to power thermal desalination processes or provide low-grade heat for industrial operations.

Managing the Edge and Specialized Workloads

The metaverse, 5G, and the proliferation of AI inferencing are driving data center operations closer to the end-user (The Edge), which demands smaller, more robust, and highly efficient cooling solutions.

Cooling for Edge Computing

Edge data centers are often deployed in non-traditional environments (e.g., cell towers, warehouses) with limited space and fluctuating external conditions. This makes traditional cooling impractical.

A. Sealed Systems: Edge deployments heavily favor sealed, closed-loop systems like single-phase immersion or specialized D2C, which protect hardware from dust, humidity, and external contaminants while eliminating the need for complex air handlers.

B. Miniaturization: Innovations focus on integrating the cooling unit (e.g., a small heat exchanger) directly into the server or rack enclosure, creating highly dense, self-contained micro-data centers.

Cooling for High-Density AI/HPC Chips

Modern AI accelerators (like advanced GPUs and specialized NPUs) have power densities that necessitate immediate and extreme cooling.

A. Advanced Dielectric Fluids: Researchers are developing next-generation dielectric fluids with superior thermal conductivity to keep these extremely hot chips within their operational limits, ensuring maximum performance and longevity.

B. Microchannel Integration: Cooling channels are being built directly into the server board and even potentially the chip packaging itself, minimizing the thermal path length and maximizing heat extraction.

The Economic and Environmental Imperative

The adoption of these advanced cooling techniques is not just a technical choice; it is a critical economic and environmental strategy.

A. Lower Total Cost of Ownership (TCO): Although the initial capital expenditure (CapEx) for liquid cooling systems can be higher than for air systems, the massive savings in operational expenditure (OpEx) driven by reduced electricity consumption for cooling and fewer hardware failures lead to a significantly lower TCO over the equipment lifecycle.

B. Regulatory Compliance and Green Initiatives: Global regulations and corporate ESG (Environmental, Social, and Governance) targets are pushing companies towards sustainable infrastructure. Lower PUE, minimized water usage, and effective heat reuse are essential metrics for meeting these mandates and improving corporate reputation.

C. Maximizing Real Estate Value: In urban areas where data center space is at a premium, liquid cooling allows operators to pack significantly more compute power into the same physical footprint. This maximizes the revenue generated per square meter, making efficient cooling a direct driver of profitability.

The Future is Fluid and Intelligent

The revelation of data center cooling innovation underscores a dramatic shift away from inefficient, noise-generating, and water-intensive air conditioning toward fluid-based, intelligent, and sustainable thermal management. The widespread adoption of Direct-to-Chip (D2C) and Immersion Cooling (both single- and two-phase) is allowing the industry to overcome the thermal barriers imposed by high-density workloads like AI and HPC. Supported by AI-driven optimization, modular deployment, and a focus on waste heat reuse, cooling has transitioned from a necessary burden to a source of competitive advantage and environmental responsibility. The future of the data center is not just about faster chips; it is about smarter cooling that enables unprecedented efficiency and density, ensuring the digital infrastructure can sustain the explosive growth of the global data economy.